Summary of the project

The project focused on software coordination and support of an automation solution for a production facility for an industrial customer in Germany. The scope of the project included management of the software part of the automation, technical coordination between the different teams and active participation in the commissioning of the plant. The solution was implemented in an industrial automation environment with emphasis on stability, modularity and compliance with IEC 61131-3 standards.

The project involved complex software coordination between the customer, the internal development team and other involved suppliers. Responsibilities included technical communication with the customer, managing software team tasks, organizing technical meetings, and ongoing project status reporting to management.

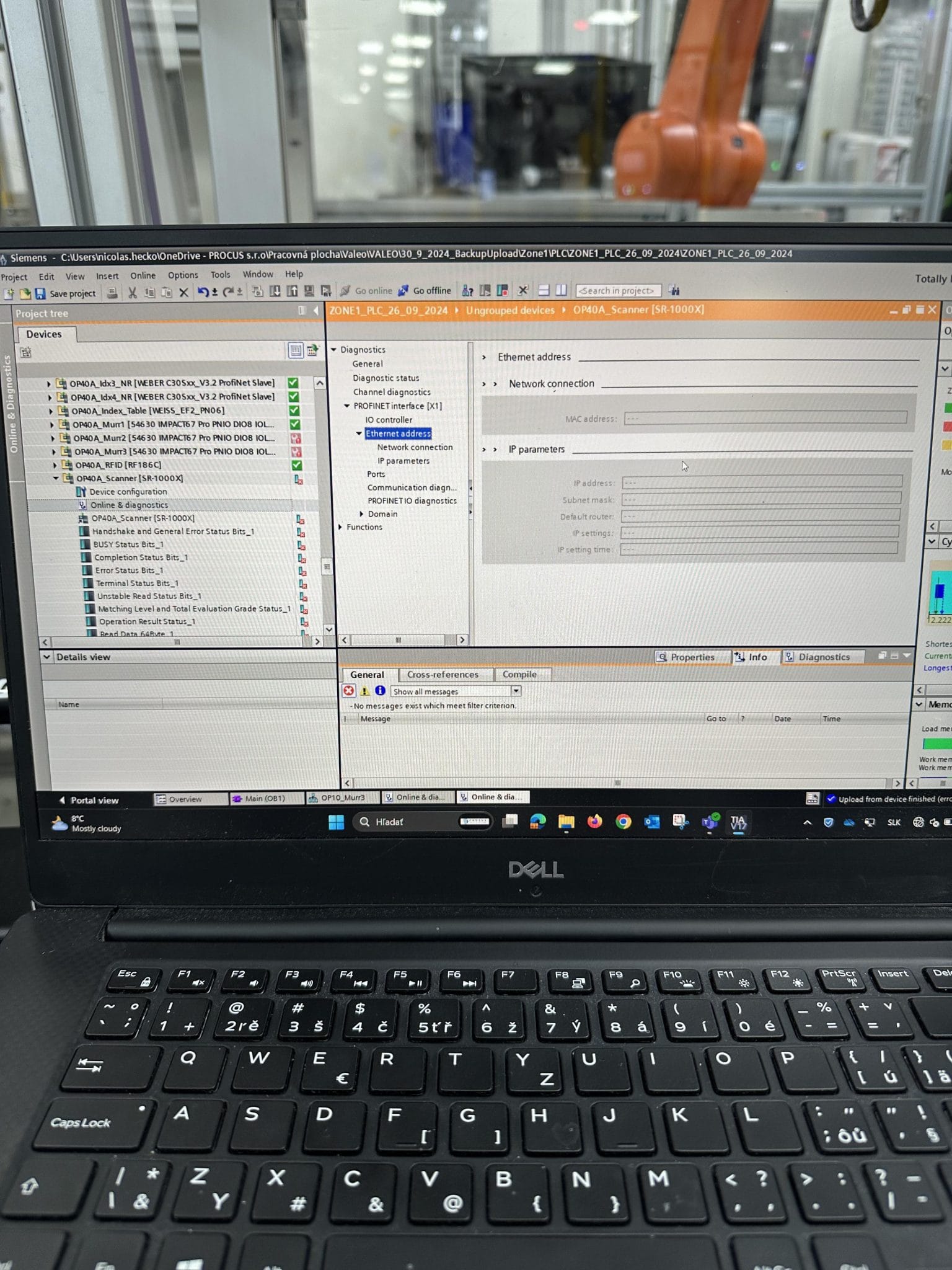

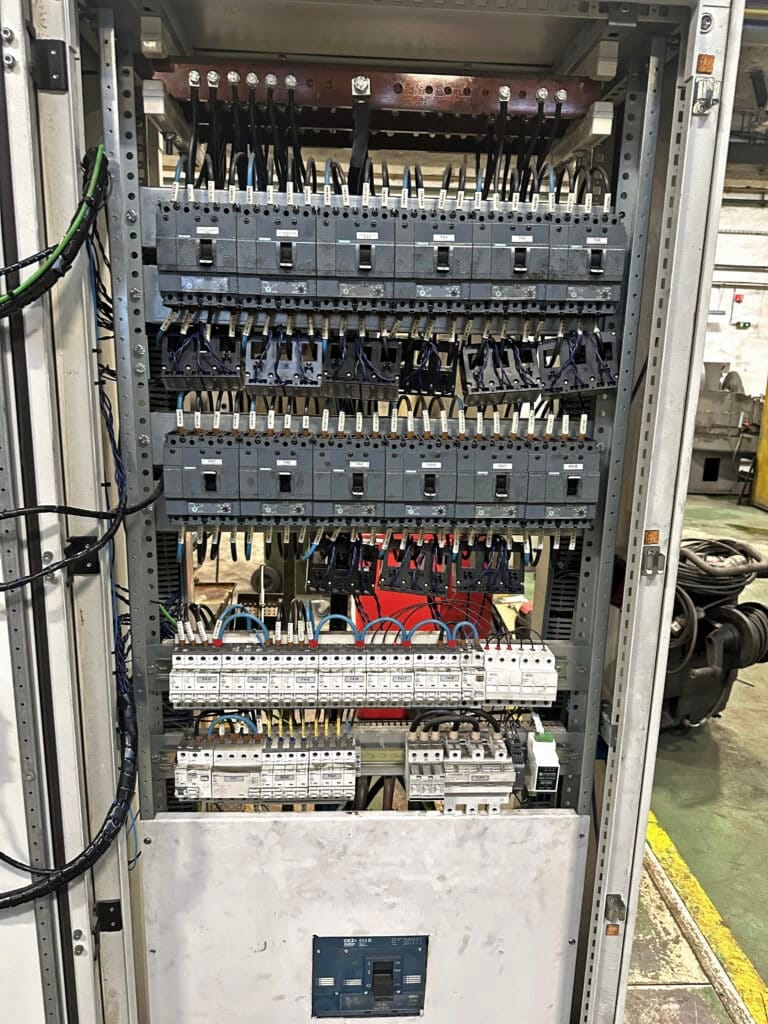

Activities included active participation in solving technical problems during the design phase as well as during installation and commissioning of the equipment at the customer’s site

Implementation

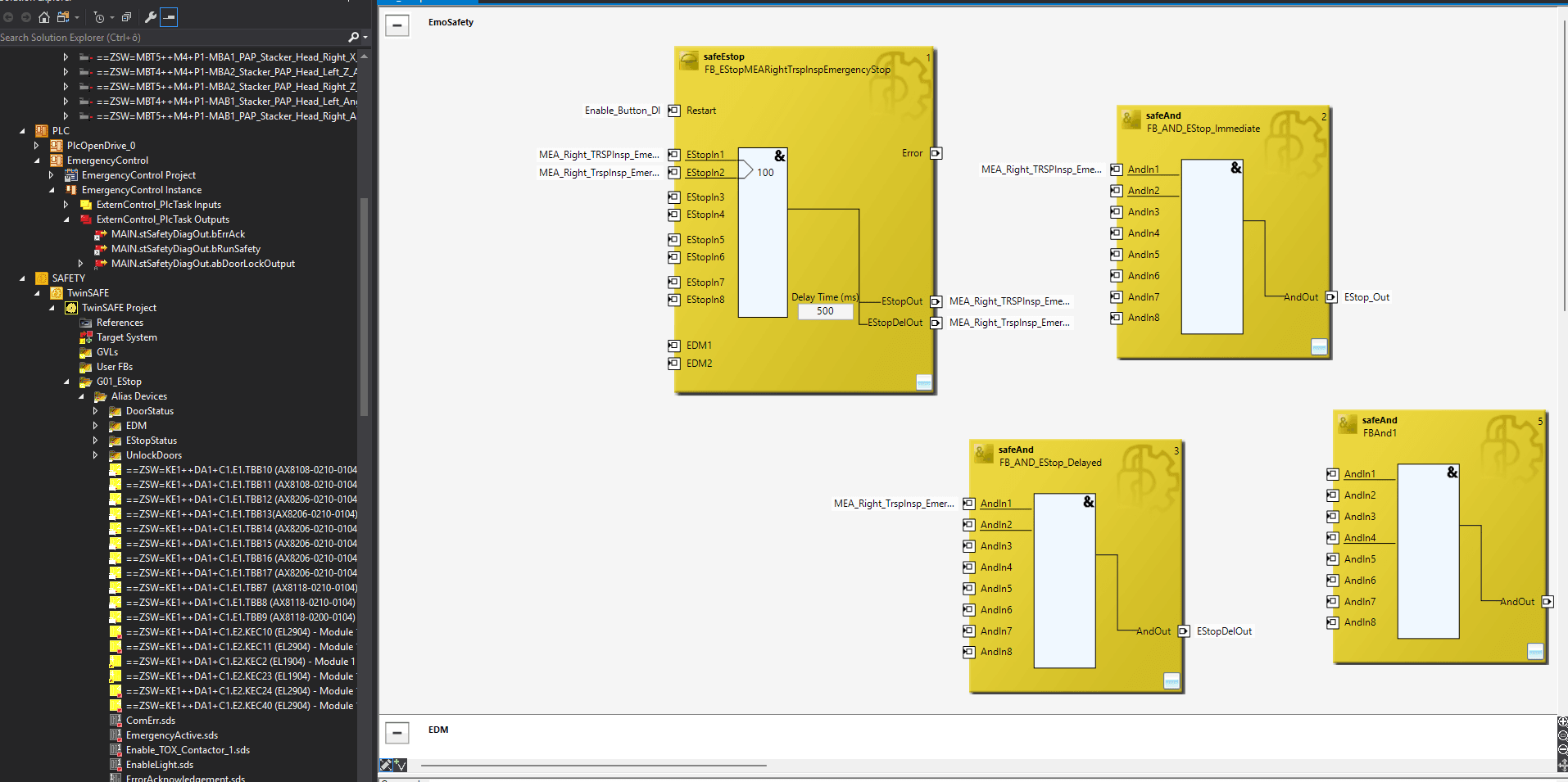

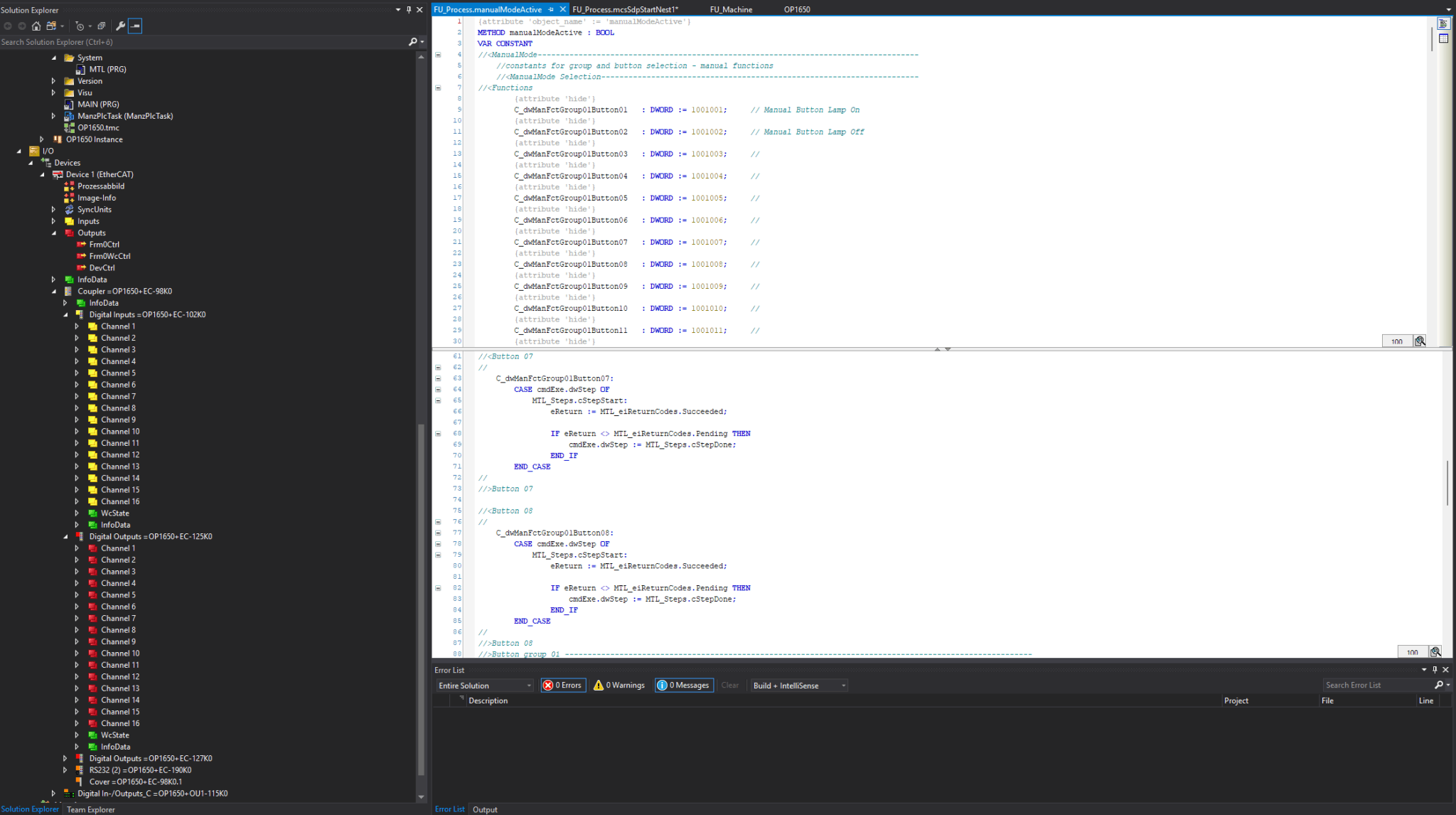

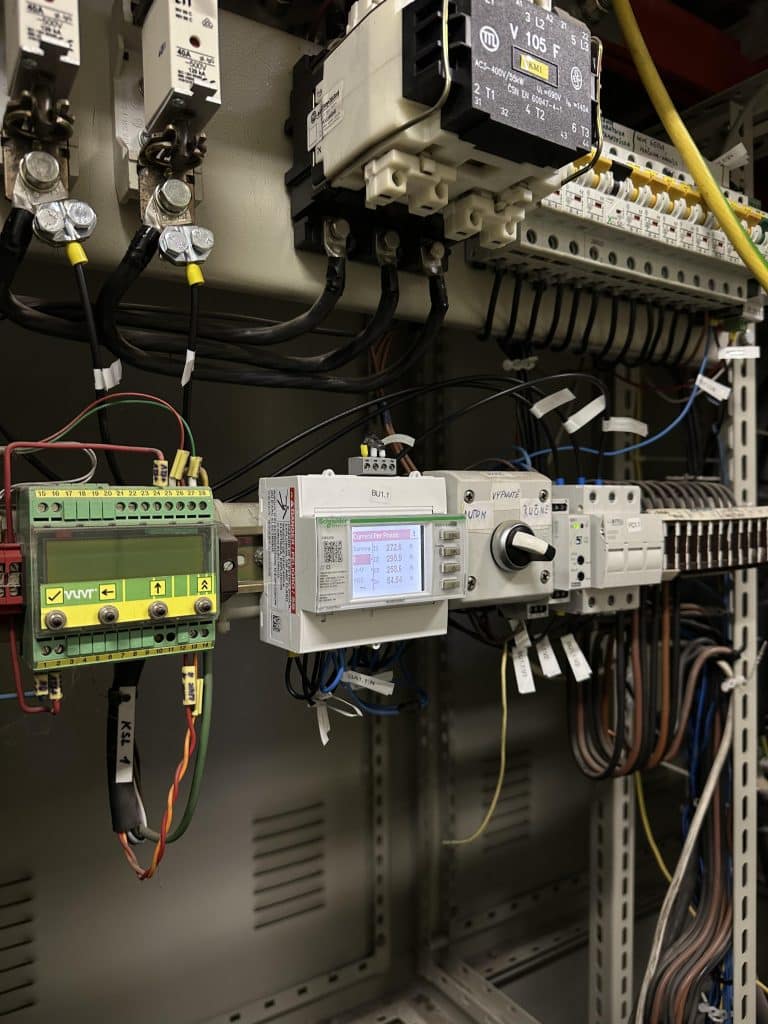

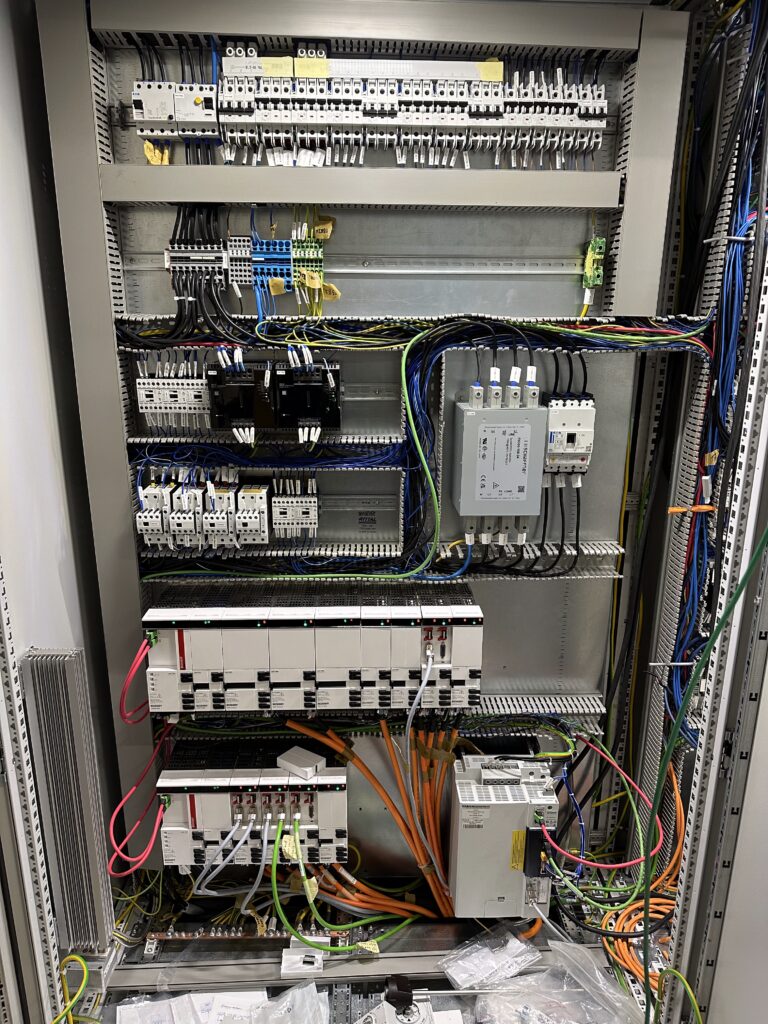

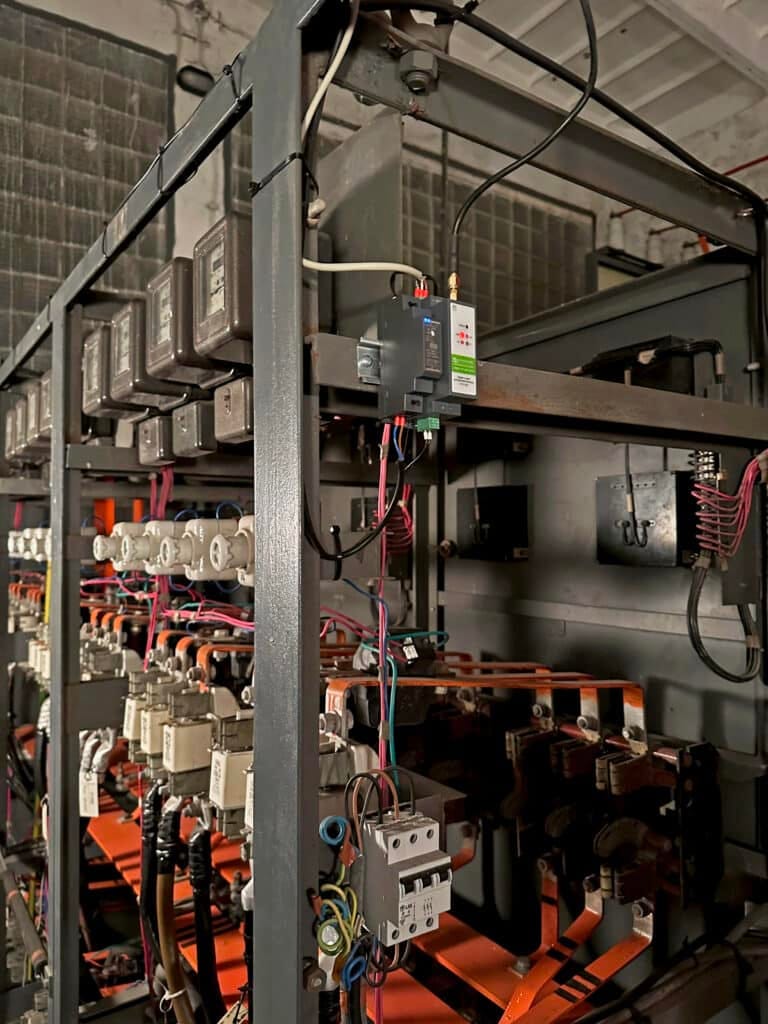

The software part of the project was implemented in the TwinCAT 3 environment using object-oriented programming according to IEC 61131-3. The scope of work included minor modifications of the PLC application software, configuration of the control system, setting of drive parameters and cooperation in the design of the software architecture of individual functional blocks.

The project also addressed communication interfaces between the individual parts of the system, integration of signals from devices and support of the HMI layer. Emphasis was placed on code readability, modularity of the solution and easy extensibility in the future.

An important part of the project was the support of the commissioning phase, both in the form of on-site presence at the customer’s site and off-site support. Activities included testing the functionality of the software, resolving bugs found during commissioning, liaising with the electrical team and making adjustments to the software based on real-life operating conditions.

The project also included ongoing documentation of changes, task logging and software version management in collaboration with the development team.

Results

The result of the project was a stable and functional software solution ready for serial operation, which met the technical requirements of the customer and enabled a smooth commissioning of the equipment. The customer received a reliable control system with a clearly defined software architecture, supported by technical documentation and a coordinated approach throughout the implementation phase.

The project created a solid foundation for further expansion of the automation solution and follow-up projects in the field of industrial automation