Summary of the project

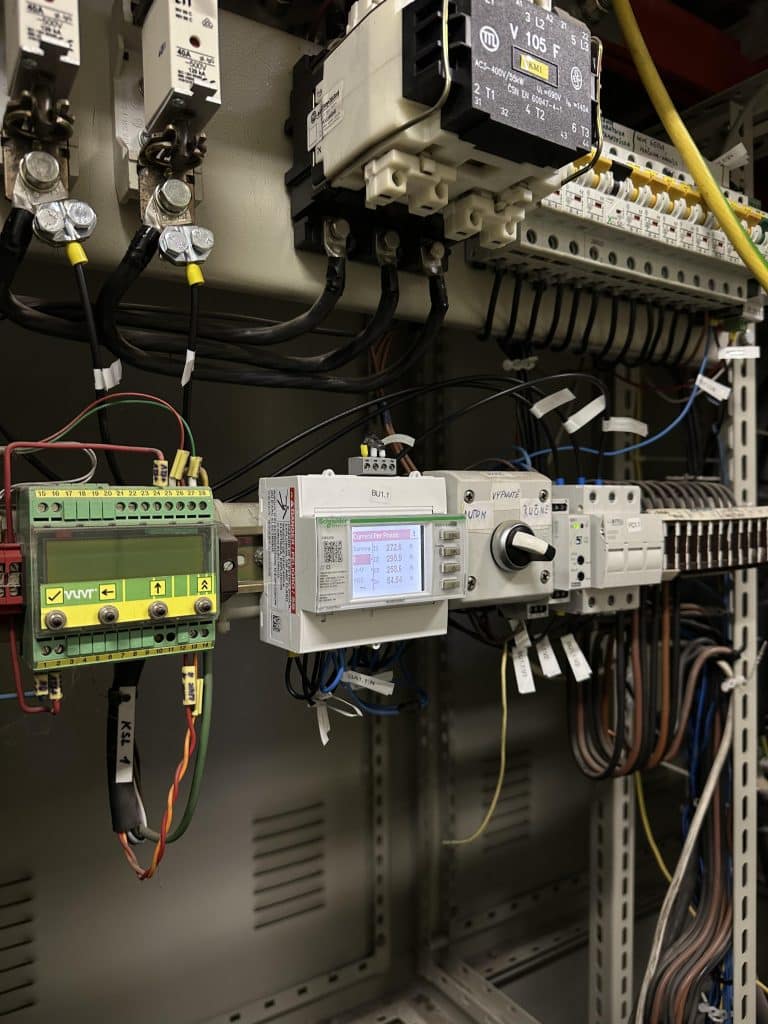

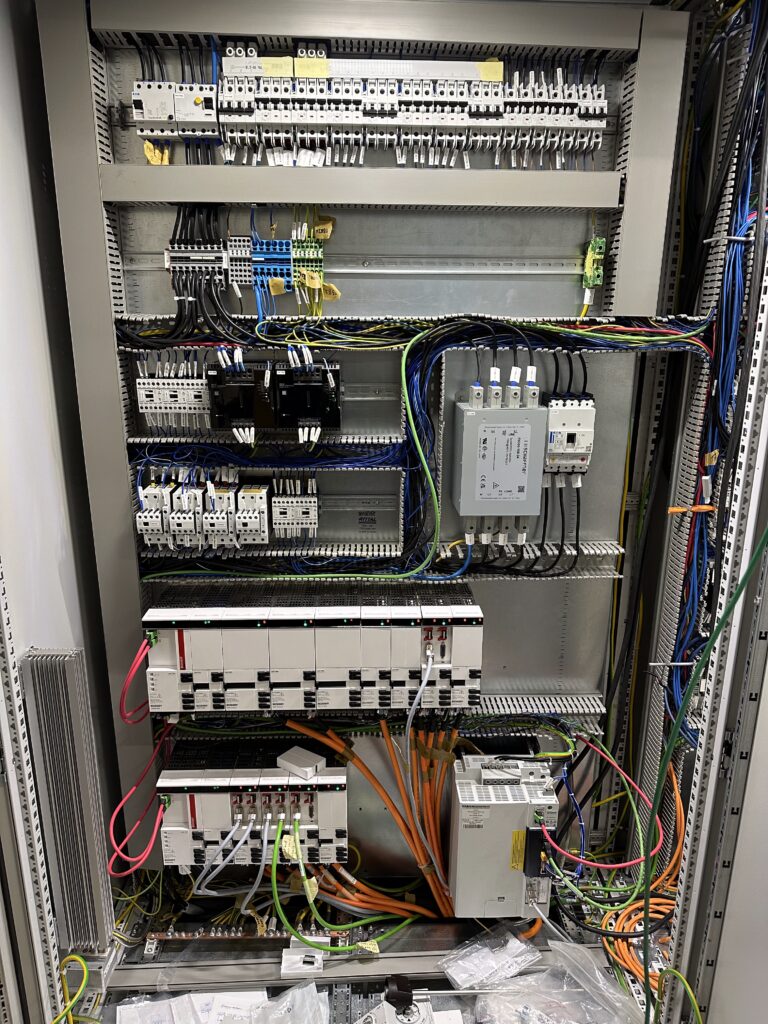

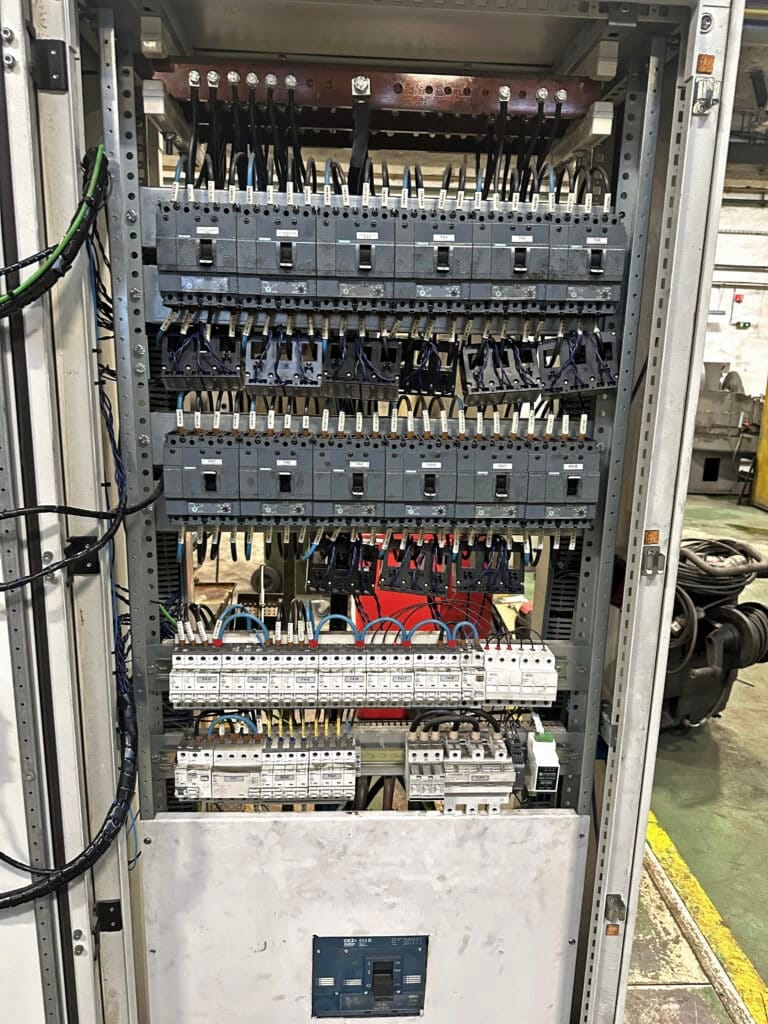

The project focused on the deployment and recovery of the control system for the process equipment. The implementation consisted of fitting VIPA I/O modules with digital inputs and outputs that provide the link between sensors and actuators.

Button panels with LED signalling have been integrated into the system to allow easy and safe operation – indicating the occupancy of the local warehouse for the production line, where the operator manually switches between empty and full warehouse, thus giving information to the operators responsible for logistics and warehouse.

The software part consisted in programming the control logic in the TIA Portal V16 environment, where we focused on repairing and reprogramming the function blocks for the existing version of the program. Subsequently, the next equally important step was to upload the program to the PLC and test it under operating conditions.

Finally, after testing the functionality of the program, we also provided services to the client in terms of creating project documentation and distortion of the actual state of the switchboard where the I/O modules were mounted.

Implementation

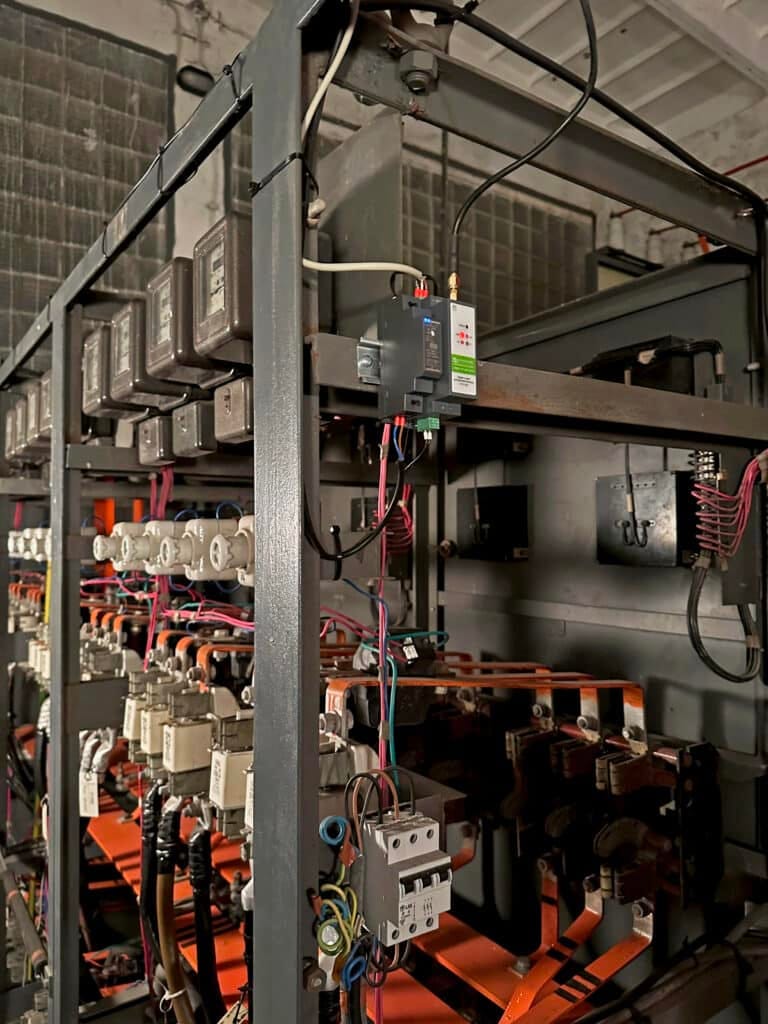

The implementation of the project consisted of several technical and software steps that ensured the full functionality of the control system. In the initial phase, I/O modules with digital inputs and outputs were installed in the switchboard to create an interface between the process sensors and the actuators of the plant. The hardware integration also included the connection of push-button panels with LED signalling, allowing manual control and visual indication of the status of the local warehouse. This feature ensured ease of use for production and logistics operators while creating a clear communication bridge between the operation and the control system.

The software part of the implementation was implemented in the TIA Portal V16 environment, where the existing control logic was modified and extended. New function blocks were added to ensure correct interpretation of signals from the panels and their subsequent processing in the control logic. After the modifications, the program was uploaded to the PLC and the process of debugging and testing in real operating conditions was carried out, thus verifying the functionality, stability and reliability of the system.

As the last stage of the implementation, project documentation was prepared, which captures the actual state of the wiring in the switchboard, including the installed I/O modules. This documentation serves not only as a technical basis for further development of the system, but also as a reference material for service and maintenance interventions in the future.

Results

Deployed functional control system integrated into the technological process.

Easy and safe operation with push button panels with LED signalling.

Modified and reprogrammed control logic in TIA Portal V16 according to operational requirements.

Verified functionality of the system directly in real operating conditions.

Submitted project documentation reflecting the actual state of wiring of the switchboard.