Summary of the project

In this project, we implemented a complex integration of secondary electricity metering in a manufacturing plant that required detailed monitoring of consumption for individual technologies in order to optimize energy management. The technical solution was based on semi-direct metering and took into account the client’s preference for connectivity via a Wi-Fi network. All collected and aggregated data is stored on a local server at the factory premises.

Measurement points

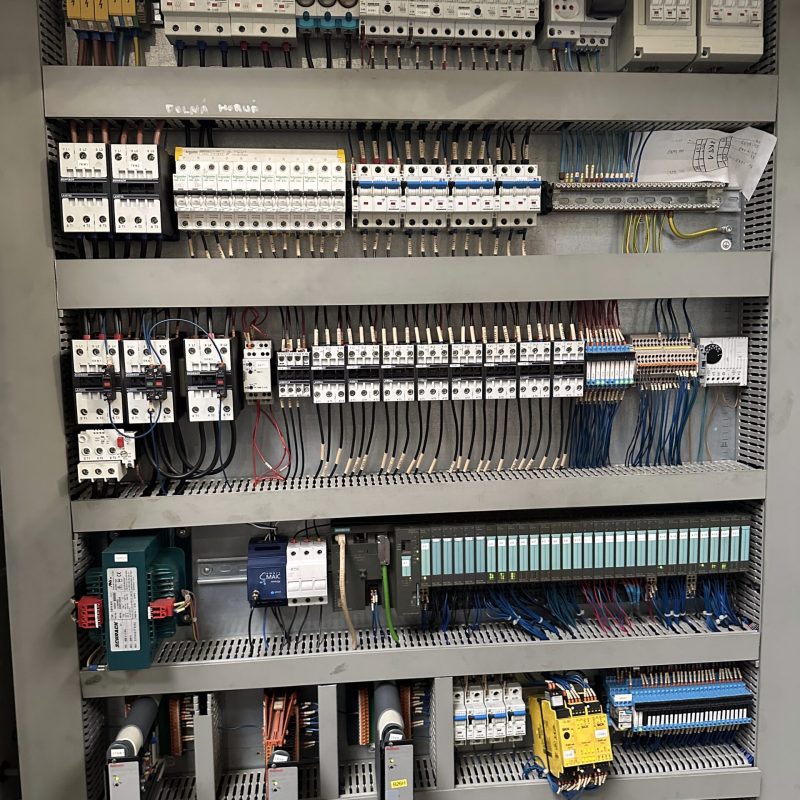

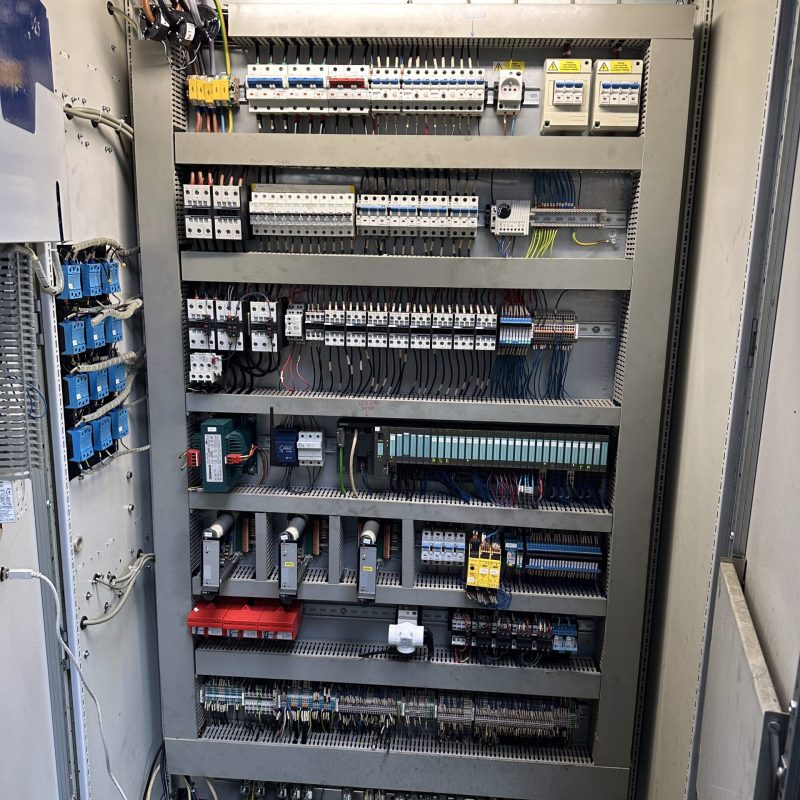

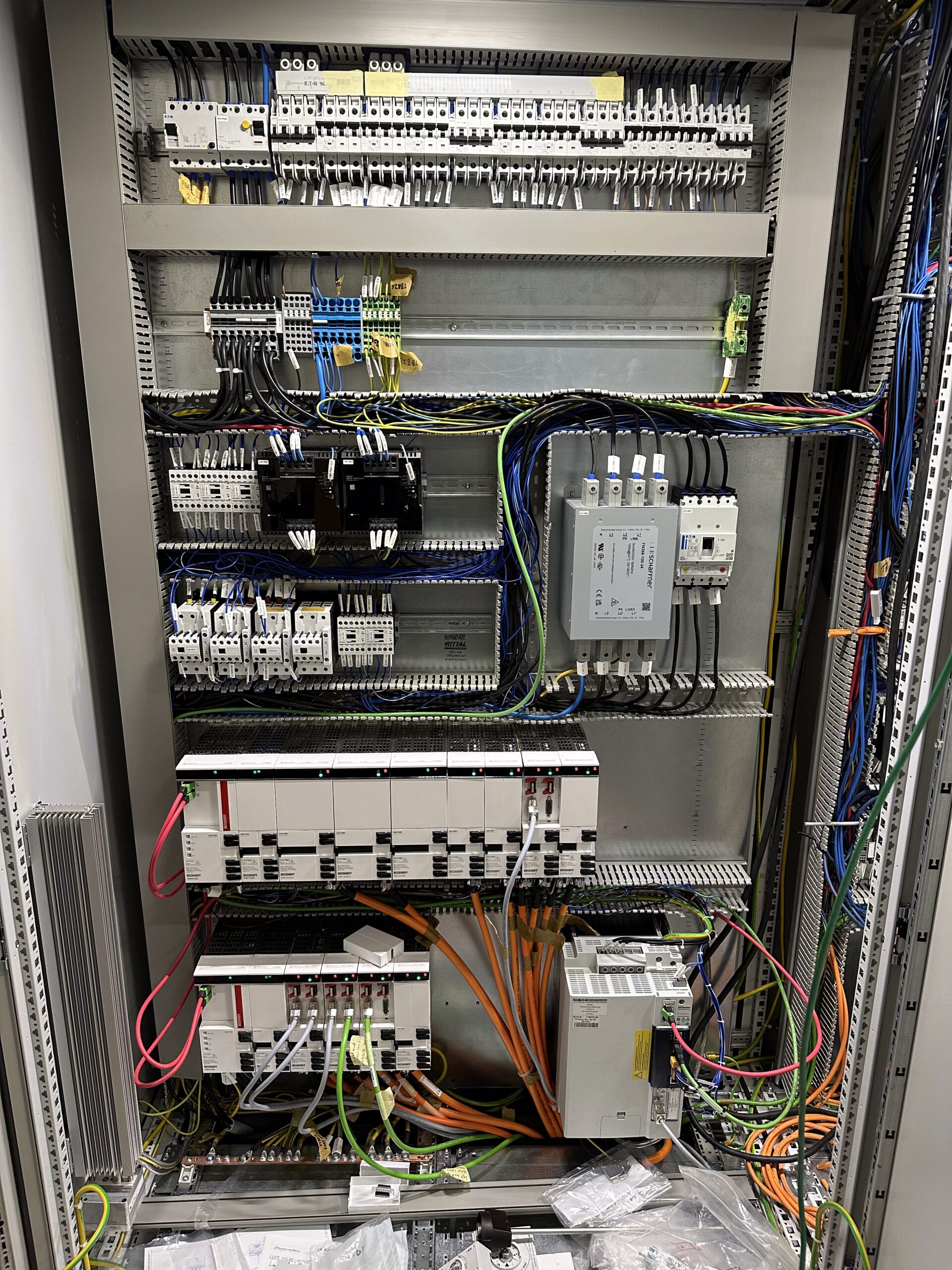

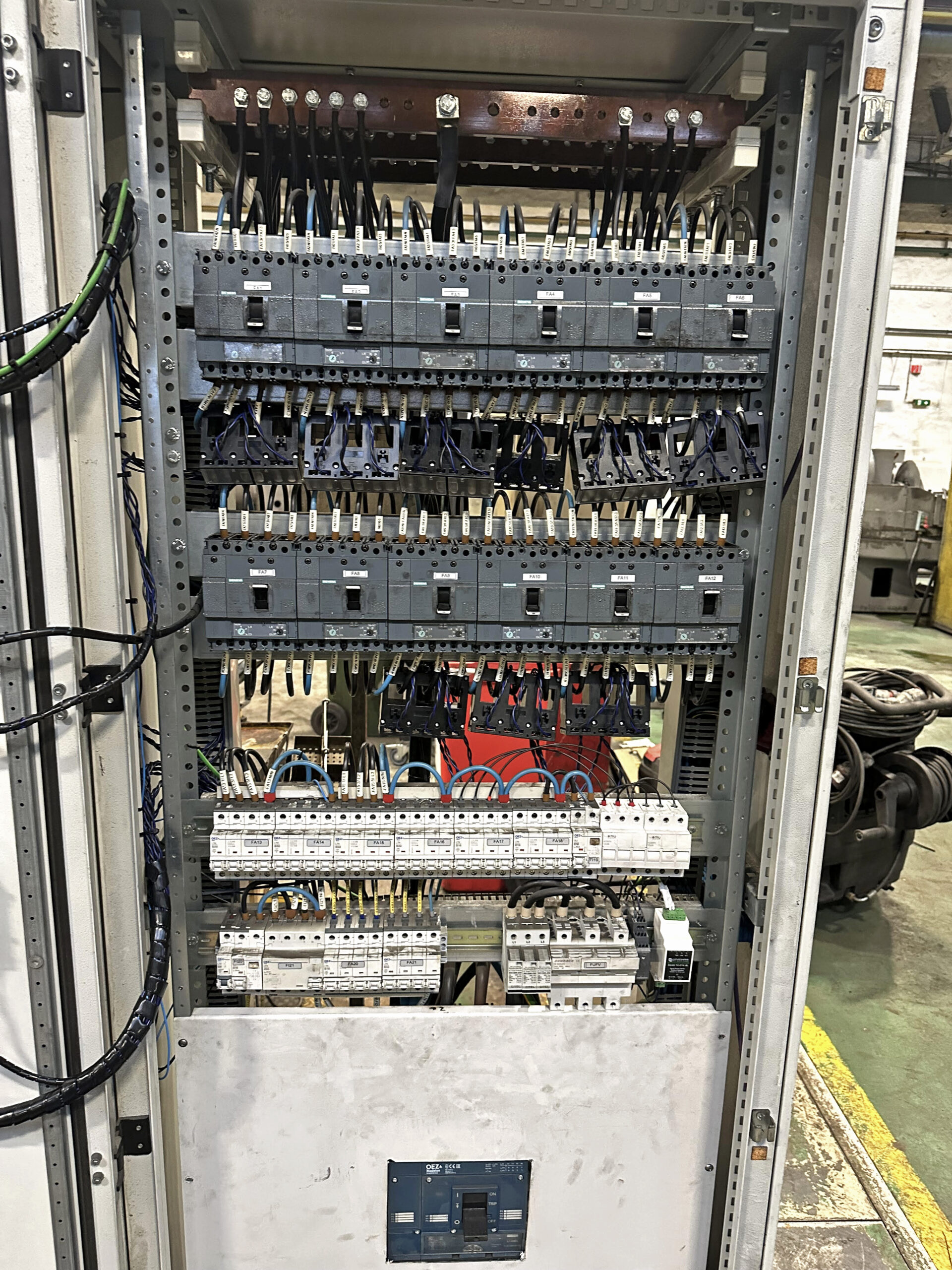

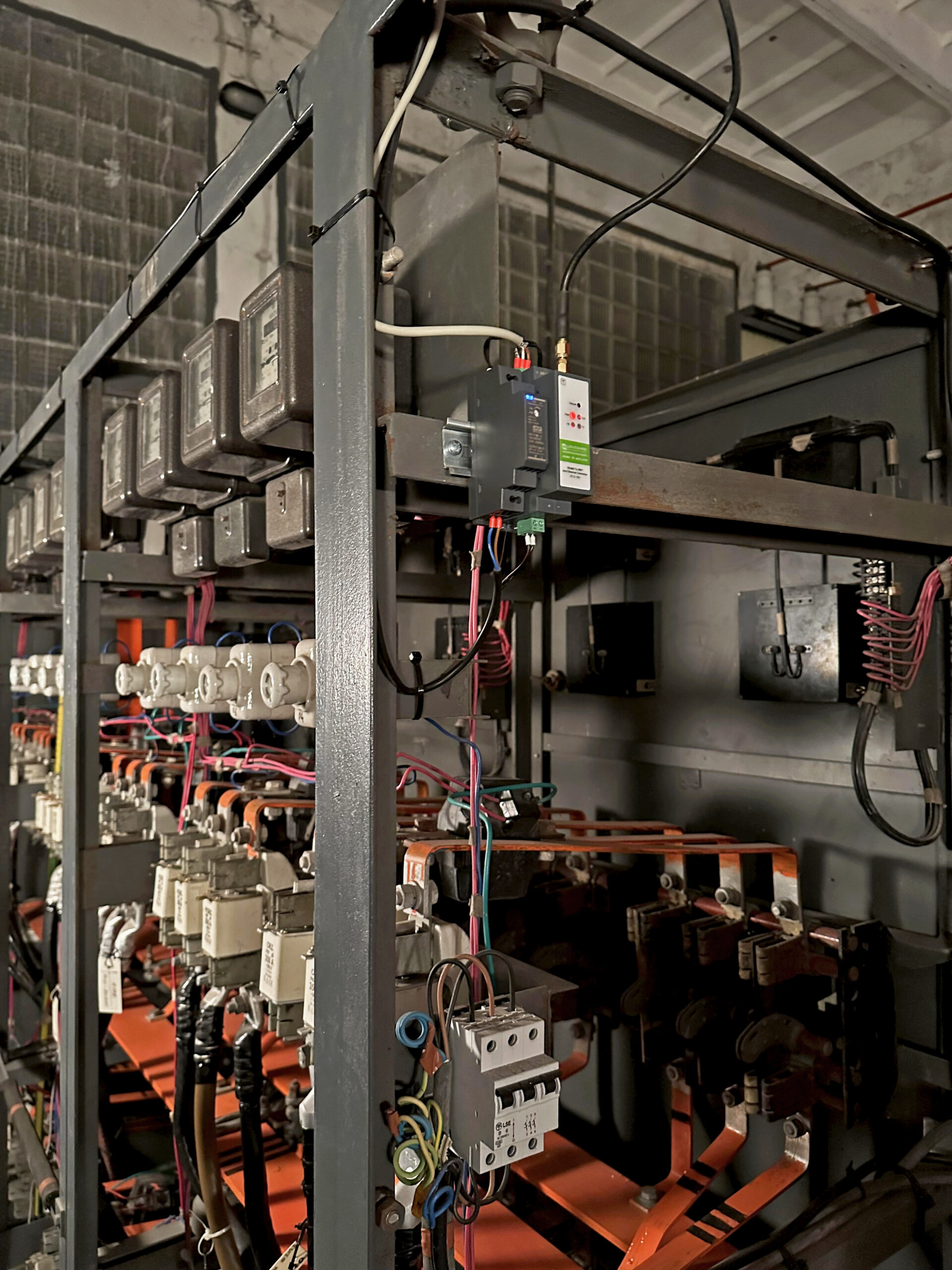

Installed electrical equipment

Implementation

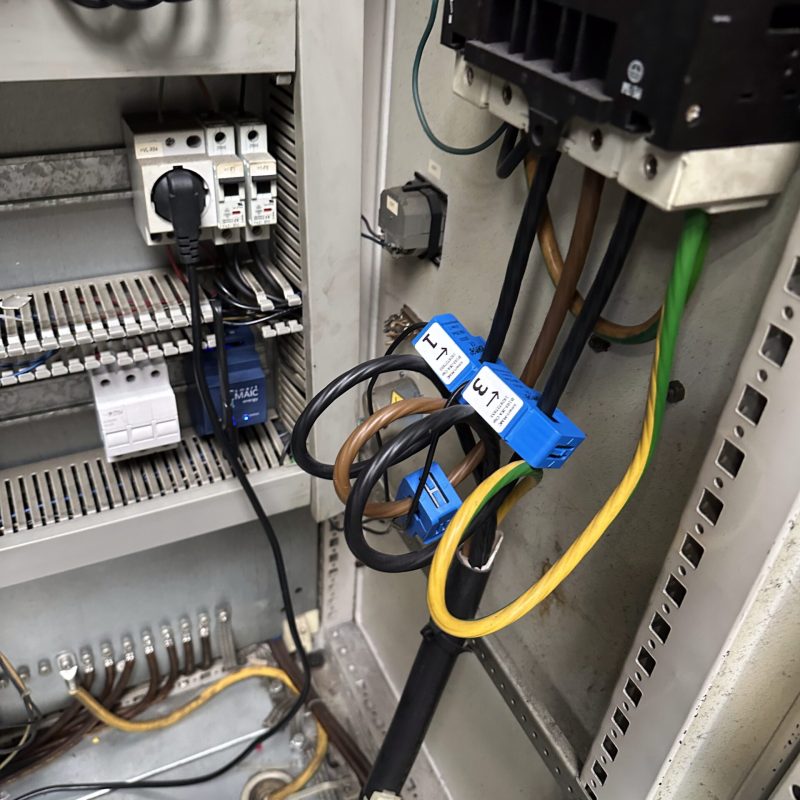

As part of the installation, we connected a total of 40 metering devices in the plant premises and 2 metering devices in the control room to ensure continuous monitoring of the total electricity consumption for the entire plant. Our key step was to connect to the existing meters providing pulses indicating current consumption. These pulses are then processed by pulse meters connected to the company’s internet network, ensuring the continuous transmission and archiving of all operational data. During the implementation, we had to deal with complications in the area of connectivity and Wi-Fi signal stability caused by significant electromagnetic interference in the plant area. After a thorough measurement of the signal strength, we concluded that the most appropriate solution would be to use external antennas. These were subsequently installed on the switchboards, giving us more reliable coverage and more stable communication.

Results

As part of the installation, we connected a total of 40 metering devices in the production areas and 2 metering devices in the control room to ensure continuous monitoring of the total electricity consumption for the entire plant. After a successful integration, we extended the project with visualization tools in cooperation with a partner company, which provide the client with useful insights and help in efficient energy management.

It is worth noting that the plant operated in three-shift continuous operation. Thanks to close cooperation with the management and technology representatives, all installation work was carried out without interrupting production, while strictly observing all occupational health and safety requirements.